Patch cables might seem like the simplest part of a structured cabling system, but the wrong choice can compromise performance, complicate installations, and even void warranties. Whether you’re terminating a security camera in a weatherproof enclosure or organizing a dense server rack, the patch cord you choose matters.

This guide breaks down when to use non-booted, booted, slim, and shielded patch cords, so you can match the right cable to the job and keep your installations clean, compliant, and built to last.

Why Patch Cable Choice Matters More Than You Think

Here’s the thing: patch cables aren’t just an afterthought. They’re part of the full channel, which means they directly impact how your system performs, whether it passes certification, and how long it lasts.

Industry standards from BICSI and TIA are pretty clear on this—your cabling system is only as good as its weakest link. Use the wrong patch cable, and you could be looking at reduced performance, extra wear on your connections, or a failed permanent-link certification.

Understanding Permanent Links and System Warranties

If you want to keep your permanent link certified, the standards require IDC terminations (such as keystone jacks or patch panels) at both ends of your premise cable. Field-terminated RJ45 plugs might work fine electrically, but they usually won’t cut it for full system warranties.

That’s where patch cords come in. They connect your certified terminations to your active equipment, letting devices plug in without messing up your compliance.

Discover the Different Patch Cord Types

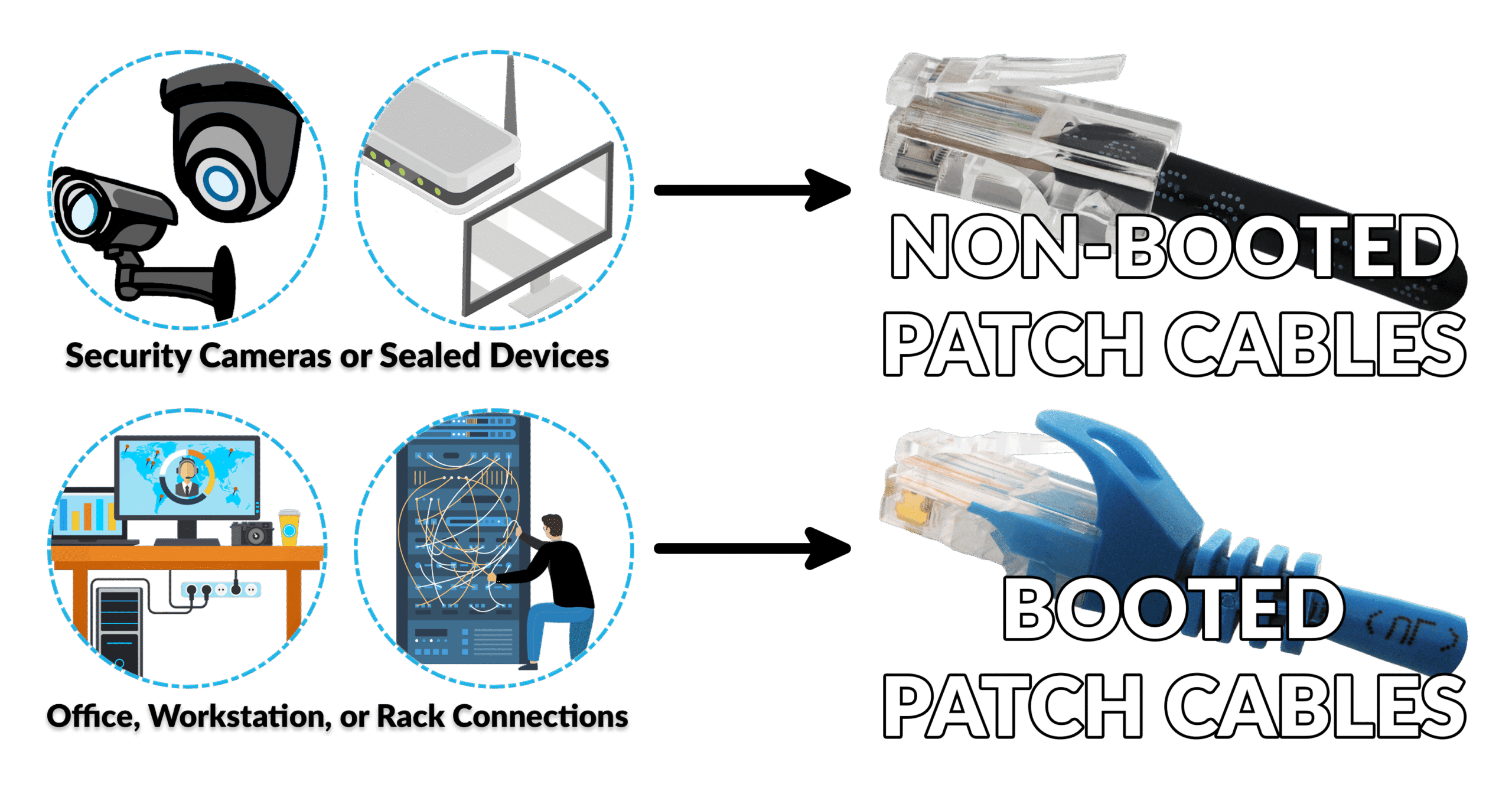

Non-Booted Patch Cords: For Tight Spots and Sealed Connections

Sometimes a molded boot just doesn’t fit. Security cameras and weatherproof devices are the classic example. They often need a bare plug to maintain their environmental seal.

Non-booted patch cords let you terminate your premise cable to a keystone while still connecting directly to the device. You get a proper termination, your warranty stays intact, and everything stays compliant.

Booted Patch Cords: The Everyday Workhorse

For most standard networking jobs, workstations, IP phones, credit card terminals, rack connections, and booted patch cords are the way to go. That molded boot takes the strain off the connector and helps the cable hold up over time, especially in areas where cables are moved around or reconnected frequently.

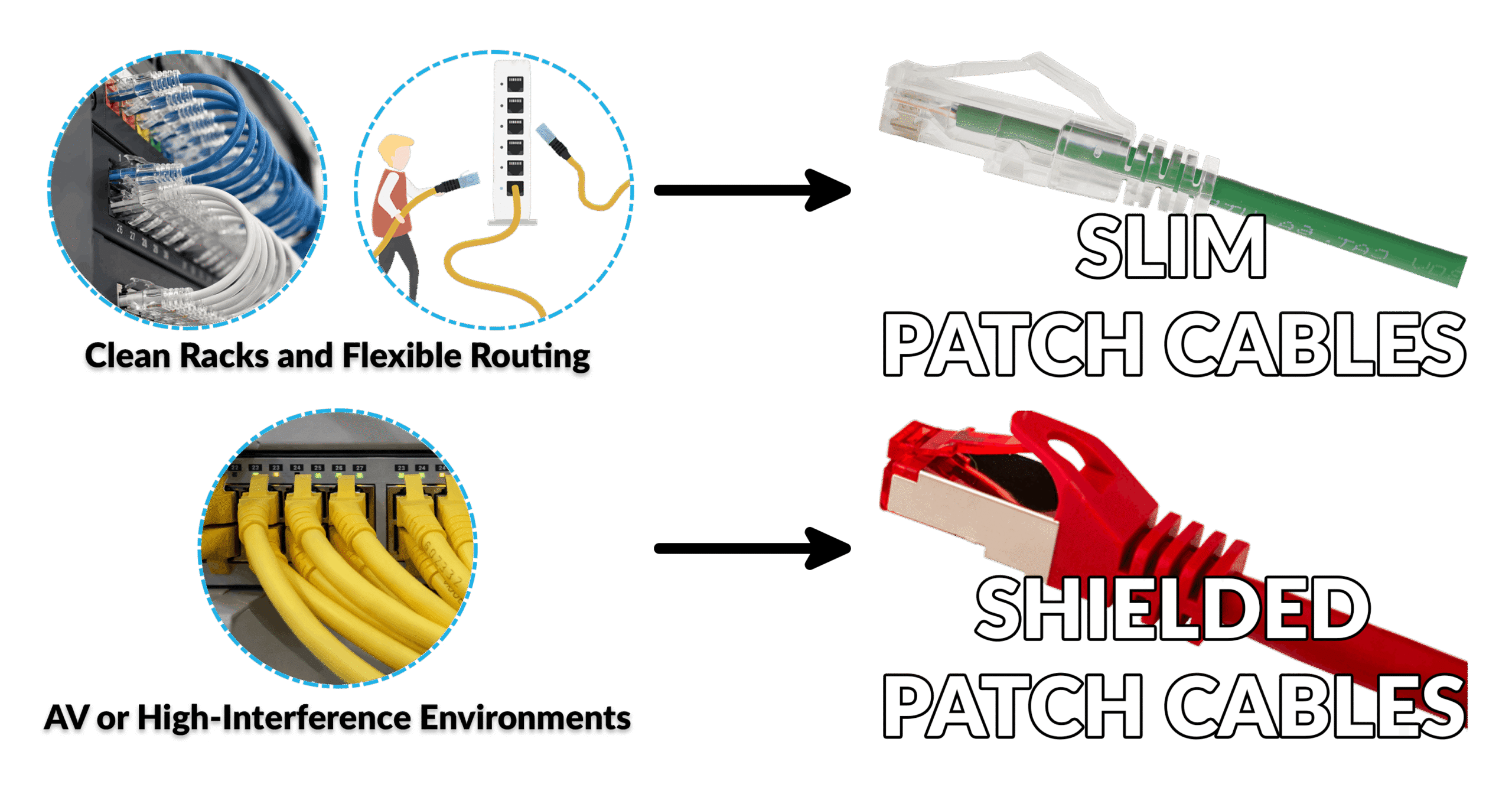

Slim CAT6A Patch Cords: For Clean Racks and Easy Routing

There’s a reason slim CAT6A patch cords have become so popular. The smaller diameter and tighter bend radius make a real difference with better airflow, easier cable management, and racks that actually look good.

Bonus: CAT6A is backward compatible with CAT6 and CAT5E systems (as long as you don’t need shielding), so you’re essentially future-proofing without sacrificing anything.

Shielded CAT6A Patch Cords: When Interference Is a Concern

If you’re working in environments with a lot of electromagnetic interference—think live AV, broadcast setups, data centers, or other mission-critical spaces—shielded patch cords aren’t optional. They’re required.

One important note: TIA standards point out that shielding only works if it’s continuous throughout the entire channel. So if the rest of your system is shielded, your patch cords need to be too.

All patch cord types are available in a variety of lengths and colors, so you can keep things organized.

Quick Patch Cable Selection Guide

If you still need help choosing a Patch Cable, check out our YouTube video.