Ruggedized armored OSP patch cords are versatile and can be used in various outdoor and demanding environments where standard patch cords may not suffice. Here are some specific applications where these cords are commonly used:

- Telecommunications: In outdoor telecom installations such as cell towers, base stations, and telecom cabinets where exposure to weather elements and physical damage is common.

- Industrial Settings: For connecting equipment and devices in industrial environments such as factories, refineries, and mining operations, where cables are exposed to dust, moisture, and rough handling.

- Military and Defense: Used in military installations, field communications, and defense applications where robustness, reliability, and resistance to harsh conditions are critical.

- Transportation: Deployed in transportation infrastructures such as railways, airports, and roadside cabinets where cables are exposed to vibration, temperature extremes, and potential vandalism.

- Utilities: In utility networks for connecting equipment in substations, power distribution systems, and outdoor installations where reliability and durability are paramount.

- Outdoor Security Systems: Used in outdoor security cameras, access control systems, and perimeter monitoring applications where cables are subjected to outdoor elements and physical stress.

- Outdoor Events: Deployed in temporary outdoor setups for events and festivals where reliable network connectivity is needed amidst varying weather conditions and environmental challenges.

- Remote Locations: Ideal for connecting remote equipment and devices in rural or isolated locations where access and maintenance can be challenging, requiring cables that can withstand outdoor conditions.

In essence, ruggedized armored OSP patch cords are designed to ensure reliable and secure connectivity in environments where standard cables would be vulnerable to damage or degradation. Their durability, weather resistance, and physical protection make them suitable for a wide range of outdoor and demanding applications across various industries.

Using armored cables in conjunction with IP-rated connectors (outlets, couplers, terminals, etc.) provides comprehensive end-to-end protection from environmental factors. Here’s how IP-rated connectors enhance the protection and functionality of armored cables:

- Sealed Against Dust and Moisture: IP-rated connectors are designed with seals and gaskets that prevent dust and moisture ingress, ensuring reliable performance in outdoor and challenging environments.

- Resistance to Water and Corrosion: These connectors are often made from materials that resist water intrusion and corrosion, prolonging the lifespan of the connection points in outdoor settings.

- Physical Protection: IP-rated connectors provide additional physical protection against impact, vibration, and accidental damage, complementing the armored construction of the cables themselves.

- Maintaining Signal Integrity: By sealing the connection points effectively, IP-rated connectors help maintain the signal integrity and minimize signal loss, critical for reliable data transmission over long distances.

- Compliance with Standards: IP ratings provide a standardized measure of protection against environmental elements, ensuring that the connectors meet specific durability and ingress protection requirements.

- Ease of Integration: IP-rated connectors are designed to be compatible with armored cables, allowing for seamless integration into outdoor network installations without compromising protection or performance.

Pairing armored cables with IP-rated connectors ensures robust protection against environmental factors, offering a reliable solution for outdoor and demanding applications where maintaining connectivity and data integrity is crucial. This combination enhances the overall reliability and longevity of the network infrastructure in challenging environments.

Using ruggedized armored OSP (Outside Plant) patch cords offers several advantages and a few considerations to keep in mind:

Pros:

- Durability: They are designed to withstand harsh environmental conditions such as extreme temperatures, moisture, and physical impact, ensuring long-lasting performance in outdoor settings.

- Physical Protection: Armored construction provides robust protection against rodents, abrasion, vandalism, and other physical hazards, reducing the risk of cable damage and downtime.

- Reliability: They offer reliable signal transmission over long distances with minimal signal loss, making them suitable for critical applications where data integrity and consistent performance are essential.

- Security: Armored OSP patch cords enhance network security by protecting against tampering and unauthorized access, ensuring the integrity and confidentiality of data transmissions.

- Versatility: They can be used in a wide range of outdoor and demanding environments, including telecommunications, industrial sites, military installations, transportation networks, and outdoor events.

- Ease of Installation: Despite their rugged design, armored OSP patch cords are typically flexible and easy to install, allowing for efficient deployment in various outdoor applications.

Cons:

- Cost: They are generally more expensive than standard patch cords due to their specialized construction and enhanced durability. The initial investment may be higher, although they can offer cost savings in terms of reduced maintenance and replacement over time.

- Weight and Bulk: Armored OSP patch cords can be heavier and bulkier than standard cables, which may require additional considerations during installation and may not be suitable for all installation scenarios.

- Flexibility Limitations: While designed to be flexible enough for outdoor use, armored OSP patch cords may have slightly less flexibility compared to their non-armored counterparts, which could affect routing in tight spaces.

- Compatibility: Some armored patch cords may require specific connectors or adapters, which could potentially limit their compatibility with existing equipment or require additional adapters for integration into certain network infrastructures.

While ruggedized armored OSP patch cords offer significant benefits in terms of durability, reliability, and security for outdoor applications, it’s essential to weigh these advantages against the potential drawbacks such as cost and installation considerations to determine the most suitable solution for specific network requirements.

When comparing regular optical fiber patch cords with ruggedized armored OSP (Outside Plant) patch cords, several key differences and considerations come into play:

Regular Optical Fiber Patch Cords:

- Indoor Use: Regular optical fiber patch cords are typically designed for indoor environments where they are protected from harsh weather conditions and physical hazards.

- Flexibility: They are generally more flexible and easier to handle compared to armored OSP patch cords, making them ideal for installations where flexibility and ease of routing are important.

- Cost: Regular optical fiber patch cords are usually less expensive than ruggedized armored OSP patch cords, primarily because they do not require the specialized armored protection.

- Application: They are commonly used in data centers, office buildings, and indoor networking environments where protection from physical damage is less of a concern.

- Maintenance: While they may require occasional replacement due to wear and tear, regular optical fiber patch cords are relatively straightforward to maintain and replace.

Ruggedized Armored OSP Patch Cords:

- Outdoor Use: Armored OSP patch cords are specifically designed for outdoor applications where they are exposed to harsh environmental conditions such as moisture, extreme temperatures, UV exposure, and physical damage.

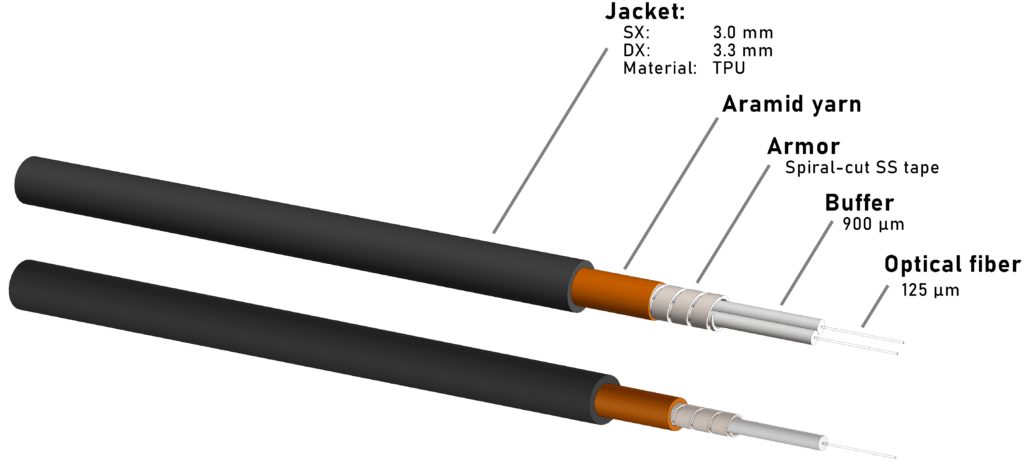

- Durability: They feature a robust armored construction (often with a layer of metal or heavy-duty polymer) that provides enhanced protection against rodent gnawing, abrasion, vandalism, and other physical impacts.

- Reliability: Armored OSP patch cords offer reliable signal transmission over long distances with minimal signal loss, making them suitable for critical outdoor applications where performance and reliability are paramount.

- Security: They enhance network security by protecting against tampering and unauthorized access, which is crucial for outdoor installations where physical security is a concern.

- Cost: Armored OSP patch cords are generally more expensive than regular patch cords due to their specialized construction and enhanced durability. However, they can provide cost savings over time by reducing maintenance and replacement needs in challenging outdoor environments.

- Installation: While they may be slightly less flexible than regular patch cords, armored OSP patch cords are designed to be flexible enough for outdoor installations and are compatible with standard connectors for easy integration into existing networks.

The choice between regular optical fiber patch cords and ruggedized armored OSP patch cords depends on the specific requirements of the installation environment. Regular patch cords are suitable for indoor use where protection from harsh outdoor conditions is not necessary, while armored OSP patch cords are essential for outdoor applications that require durability, reliability, and enhanced physical protection.

Testing armored patch cords versus regular optical fiber cords generally requires similar equipment, but there are some considerations due to the armored nature of OSP patch cords:

- Visual Inspection Tools:

- Fiber Microscopes: Used to inspect the end faces of connectors for cleanliness and damage.

- Video Inspection Probes: Can be used for more detailed inspection, especially useful for armored cables where physical damage may occur.

- Insertion Loss and Return Loss Testing:

- Light Source and Power Meter (LSPM): Used to measure insertion loss (attenuation) of the fiber optic cable.

- OTDR (Optical Time Domain Reflectometer): Provides more detailed analysis of the fiber optic cable, including length, splice losses, connectors, and overall attenuation.

- Special Considerations for Armored Patch Cords:

- Armored patch cords may require specific adapters or accessories due to their larger diameter and ruggedized construction.

- The connectors on armored patch cords may be different from standard connectors, so ensuring compatibility with testing equipment is important.

- Environmental Testing:

For OSP patch cords, environmental testing may be necessary to ensure they can withstand conditions such as temperature extremes, moisture, and physical stress.

- Documentation and Reporting:

Keeping detailed records of testing results and any anomalies found during testing is important for troubleshooting and maintenance.

While the basic equipment for testing regular optical fiber cords can also be used for armored patch cords, there may be some specific considerations and adjustments needed due to the armored construction and potential differences in connectors. Ensuring compatibility and proper handling during testing will help maintain the integrity and reliability of the network installation.